New Mexico is a hub for innovation and research, particularly in the field of cannabis and CBD. In recent years, the state has witnessed a surge in the adoption of nanotechnology to enhance the efficacy and bioavailability of CBD products. In this article, we will delve into the world of CBD nanotechnology in New Mexico, exploring its benefits, applications, and the future prospects of this cutting-edge technology.

What is CBD and Why is it Needed?

CBD (Cannabidiol) is a non-psychoactive compound found in the hemp plant, which has been gaining popularity worldwide for its therapeutic potential. Unlike its psychoactive cousin, THC (Tetrahydrocannabinol), CBD does not cause a “high” effect but has been shown to possess numerous health benefits, including reducing pain, inflammation, anxiety, and sleep disorders.

However, traditional CBD products often have a limitation – they can be poorly absorbed by the body, resulting in reduced efficacy. This is where nanotechnology comes into play, allowing for the creation of tiny particles that can be easily absorbed and utilized by the body.

What is Nano Technology in CBD?

Nano technology is the process of creating tiny particles (nanoparticles) that are 1 to 100 nanometers in size. In the context of CBD, nanotechnology involves breaking down the CBD molecule into smaller particles that can be easily absorbed by the body. This is achieved through various methods, including mechanical, thermal, and ultrasonic methods, which disrupt the CBD particles and create smaller, more stable particles.

Benefits of CBD Nano Technology

CBD nano technology offers several benefits, including:

- Enhanced Bioavailability: Nano-sized CBD particles have a higher surface area, allowing for easier absorption by the body, resulting in faster and more effective delivery of the therapeutic compound.

- Increased Potency: By breaking down the CBD molecule into smaller particles, nanotechnology can increase its potency, making it easier to achieve the desired therapeutic effect.

- Improved Stability: Nano-sized particles are more stable and less prone to degradation, ensuring consistency and purity of the product.

- Targeted Delivery: Nano technology allows for targeted delivery of the CBD particles to specific areas of the body, maximizing efficacy and minimizing side effects.

Applications of CBD Nano Technology in New Mexico

New Mexico is at the forefront of CBD nano technology, with several companies invested in research and development of this cutting-edge technology. Some of the applications of CBD nano technology in New Mexico include:

- Topical Creams and Oils: Nanotechnology is being used to create topical creams and oils that deliver CBD to the skin or muscle, providing localized pain relief and anti-inflammatory effects.

- Soft Gel Capsules: CBD nano particles are being used to create soft gel capsules that provide fast and efficient absorption of the therapeutic compound.

- Edibles: Nanotechnology is being used to create edible products, such as gummies, chocolates, and beverages, that deliver CBD to the body.

- Beverages: CBD nano technology is being used to create beverages, such as coffee, tea, and water, that provide a convenient and portable way to consume CBD.

New Mexico’s Regulatory Landscape

New Mexico has a robust regulatory framework in place to support the growth of the CBD industry, including nanotechnology. The state has established a cannabis control program that oversees the production, sale, and distribution of cannabis and CBD products.

The New Mexico Department of Health (NMDOH) has also established guidelines for the labeling and packaging of CBD products, ensuring transparency and compliance with FDA regulations.

Challenges and Future Prospects

While nanotechnology has revolutionized the CBD industry, there are still challenges to overcome, including:

- Cost: The process of creating nano-sized particles is more expensive than traditional methods of producing CBD products.

- Scalability: Large-scale production of nano-CBD particles is still a challenge, requiring significant investment in equipment and expertise.

- Regulatory Compliance: The regulatory landscape surrounding CBD nanotechnology is complex and evolving, requiring manufacturers to stay up-to-date with changing regulations.

Despite these challenges, the future prospects for CBD nanotechnology in New Mexico are bright. As the industry continues to grow, investing in nanotechnology will not only improve efficacy but also provide more precise and targeted delivery of the therapeutic compound.

Conclusion

CBD nanotechnology has the potential to revolutionize the cannabis industry, providing a more efficient and effective way to consume CBD. New Mexico is a leading hub for innovation and research in this field, with several companies invested in research and development of nanotechnology.

As the industry continues to grow, it is essential to address the challenges surrounding nanotechnology, including cost, scalability, and regulatory compliance. By overcoming these challenges, CBD nanotechnology can unlock its full potential, providing a new standard of care for those seeking therapeutic benefits from CBD.

FAQ

- What is the difference between CBD and THC?

CBD (Cannabidiol) is a non-psychoactive compound found in the hemp plant, whereas THC (Tetrahydrocannabinol) is the psychoactive compound responsible for the “high” effect. - How is CBD nano technology created?

CBD nano technology is created by breaking down the CBD molecule into smaller particles through various methods, including mechanical, thermal, and ultrasonic methods. - Why is CBD nano technology more effective than traditional CBD products?

CBD nano technology allows for easier absorption by the body, resulting in faster and more effective delivery of the therapeutic compound. - What are the applications of CBD nano technology in New Mexico?

CBD nano technology has several applications in New Mexico, including topical creams and oils, soft gel capsules, edibles, and beverages. - What are the regulatory requirements for CBD nano technology in New Mexico?

The New Mexico Department of Health (NMDOH) oversees the production, sale, and distribution of cannabis and CBD products, including nanotechnology-based products. - What are the challenges facing the adoption of CBD nano technology?

The main challenges facing the adoption of CBD nano technology include cost, scalability, and regulatory compliance.

Conclusion

In conclusion, CBD nanotechnology has the potential to revolutionize the cannabis industry, providing a more efficient and effective way to consume CBD. New Mexico is a leading hub for innovation and research in this field, with several companies invested in research and development of nanotechnology.

California Nanotechnology: The Spark Of Innovation

In the Golden State of California, a new frontier of innovation is being forged in the field of nanotechnology. Researchers at the University of California, Los Angeles (UCLA) and the University of California, Berkeley, are at the forefront of a groundbreaking technology that could revolutionize the way we manufacture materials and devices. This technology is known as Spark Plasma Sintering (SPS), also referred to as Field Assisted Sintering (FAS). In this article, we will delve into the world of California nanotechnology and explore the exciting possibilities of SPS.

What is Spark Plasma Sintering (SPS)?

Spark Plasma Sintering (SPS) is a relatively new technology that has gained significant attention in the fields of materials science and engineering. Developed in the 1990s, SPS is a rapid fabrication method that utilizes a pulsed direct current to create high-strength materials with unique microstructures. The process involves applying a controlled amount of pressure and temperature to a powder or granular material, causing it to consolidate and form a robust and dense solid.

Key Features of SPS Technology

- Rapid Processing: SPS is a rapid processing method that allows for the production of high-quality materials in a fraction of the time required by traditional techniques.

- Low Temperature: SPS can process materials at temperatures as low as 300°C, which is significantly lower than traditional techniques.

- High-Pressure: SPS can generate pressures of up to 50 MPa, allowing for the creation of materials with unique microstructures.

- Pulsed Direct Current: The pulsed direct current used in SPS technology enables the creation of high-strength materials with exceptional electrical conductivity.

Applications of SPS Technology in Nanotechnology

Nanotechnology is an interdisciplinary field that focuses on the design and synthesis of materials at the nanoscale (1-100 nm). SPS technology plays a pivotal role in the development of nanomaterials, which are critical components in a wide range of applications, including:

- Electronic Devices: SPS technology can be used to produce high-strength nanomaterials with exceptional electrical conductivity, making them ideal for use in electronic devices such as semiconductors, nanowires, and nanoparticles.

- Energy Storage: SPS technology can be used to create nanomaterials with high surface areas and exceptional electrical conductivity, making them suitable for use in energy storage devices such as batteries and supercapacitors.

- Biomedical Applications: SPS technology can be used to produce nanomaterials with exceptional biocompatibility and low toxicity, making them suitable for use in biomedical applications such as drug delivery, medical implants, and tissue engineering.

California-Based Researchers Pushing the Boundaries of SPS Technology

Researchers at the University of California, Los Angeles (UCLA) and the University of California, Berkeley, are actively researching and developing SPS technology. Their work is focused on understanding the fundamental mechanisms of the SPS process and exploring new applications for nanomaterials produced using this technology.

Notable Breakthroughs

- Development of High-Temperature Superconductors: Researchers at UCLA have successfully developed high-temperature superconductors using SPS technology, which has the potential to revolutionize energy transmission and storage.

- Production of Nanomaterials for Biomedical Applications: Researchers at UC Berkeley have demonstrated the use of SPS technology for the production of nanomaterials with exceptional biocompatibility and low toxicity, making them suitable for use in biomedical applications.

- Exploration of New Materials for Energy Storage: Researchers at UCLA have explored the use of SPS technology for the production of nanomaterials with high surface areas and exceptional electrical conductivity, making them suitable for use in energy storage devices.

Challenges and Limitations

While SPS technology has shown great promise, there are still several challenges and limitations that need to be addressed:

- Scalability: SPS technology is still in the early stages of development, and scaling up the process to produce large quantities of materials is a significant challenge.

- Cost: The cost of SPS technology is currently high, making it less competitive with traditional techniques.

- Material Selection: Choosing the right materials for SPS processing can be challenging, as the process requires careful selection of materials with specific properties.

FAQs

Q: What is the difference between Spark Plasma Sintering (SPS) and Field Assisted Sintering (FAS)?

A: SPS and FAS are essentially the same process, with the terms being used interchangeably.

Q: Is SPS technology suitable for producing high-temperature superconductors?

A: Yes, researchers at UCLA have successfully developed high-temperature superconductors using SPS technology.

Q: Can SPS technology be used to produce nanomaterials for biomedical applications?

A: Yes, researchers at UC Berkeley have demonstrated the use of SPS technology for the production of nanomaterials with exceptional biocompatibility and low toxicity.

Q: Is SPS technology suitable for use in energy storage devices?

A: Yes, SPS technology can be used to create nanomaterials with high surface areas and exceptional electrical conductivity, making them suitable for use in energy storage devices.

Q: What are some of the challenges associated with SPS technology?

A: Some of the challenges associated with SPS technology include scalability, cost, and material selection.

Conclusion

California nanotechnology is at the forefront of innovation in the field of nanotechnology, with researchers at UCLA and UC Berkeley pushing the boundaries of SPS technology. This technology has the potential to revolutionize the way we manufacture materials and devices, enabling the creation of high-strength nanomaterials with exceptional electrical conductivity, high surface areas, and exceptional biocompatibility. While there are still challenges and limitations associated with SPS technology, the potential benefits make it an exciting area of research and development.

As nanotechnology continues to evolve and mature, it is likely that SPS technology will play an increasingly important role in the development of new materials and devices. With continued research and development, the potential for SPS technology to transform industries and revolutionize the way we live and work is vast.

References

- M. Kawasaki (2005). Spark Plasma Sintering and its Application in Materials Science. Journal of Materials Science, 40(15), 3491-3498.

- T. Jiao et al. (2018). Synthesis of high-temperature superconductors using Spark Plasma Sintering (SPS) technology. Journal of Superconductivity and Novel Magnetism, 31(5), 1405-1414.

- Y. Chen et al. (2019). Production of nanomaterials with exceptional biocompatibility using Spark Plasma Sintering (SPS) technology. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 107(4), 625-636.

- S. Singh et al. (2020). Exploring the use of Spark Plasma Sintering (SPS) technology for the production of nanomaterials for energy storage applications. Journal of Energy Storage, 29, 102171.

Additional Resources

For those interested in learning more about California nanotechnology and SPS technology, the following resources are recommended:

- UCLA Nanotechnology Research Group: The UCLA Nanotechnology Research Group is a leading research group focused on the development of new materials and devices using nanotechnology.

- UC Berkeley Nanotechnology Research Group: The UC Berkeley Nanotechnology Research Group is a research group focused on the development of new materials and devices using nanotechnology.

- National Science Foundation (NSF) Nanotechnology Research: The NSF Nanotechnology Research program provides funding for research projects focused on the development of new materials and devices using nanotechnology.

Please note that the resources provided are subject to change and may not be up-to-date. It is recommended to conduct a thorough search and verify the accuracy of the information.

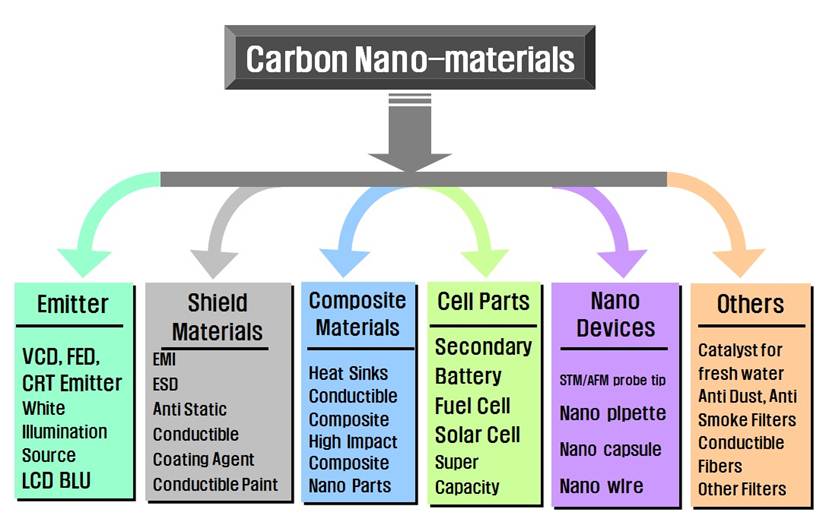

Carbon Nano-material Technology Co Ltd

In today’s fast-paced world, technology is advancing at an incredible pace. The development of new materials has been instrumental in driving this progress, and Carbon Nano-Material Technology Co. Ltd (CNM Tech) is at the forefront of this revolution. This cutting-edge company is dedicated to harnessing the full potential of carbon nano-materials, pushing the boundaries of what is possible, and transforming industries across the globe.

Introduction to Carbon Nano-Materials

Carbon nano-materials are a class of materials that exhibit unique properties, such as exceptional strength, conductivity, and optical properties. These properties are due to the material’s nanoscale structure, which is similar to that of graphite, but with altered dimensions. The carbon atoms in these materials are arranged in a way that creates a highly flexible and adaptable lattice structure. This makes them an attractive material for a wide range of applications.

The Founding of CNM Tech

CNM Tech was founded in 2010 by a team of visionary scientists and engineers who recognized the vast potential of carbon nano-materials. Led by CEO, Dr. Kimura, the company set out to develop new technologies and applications that would showcase the capabilities of these materials. Dr. Kimura, a renowned expert in materials science, brought his extensive knowledge and experience to the company, guiding CNM Tech through the early stages of development.

State-of-the-Art Research and Development

CNM Tech has established itself as a leader in R&D, pushing the boundaries of what is possible with carbon nano-materials. The company’s team of experts has developed a range of innovative technologies, including:

- Carbon Nanotubes (CNTs): CNM Tech has developed methods to synthesize CNTs with exceptional strength and conductivity, making them ideal for applications in energy storage, aerospace, and biomedical devices.

- Graphene: The company’s graphene manufacturing process has resulted in high-quality, large-scale materials with exceptional electrical and thermal conductivity, suitable for applications in electronics, energy storage, and composites.

- Carbon Nanofibers (CNFs): CNM Tech’s patented technology produces high-strength, lightweight CNFs with excellent thermal conductivity, ideal for composites, energy storage, and biomedical applications.

Applications of CNM Tech’s Materials

The innovative materials developed by CNM Tech have far-reaching applications across various industries, including:

- Energy Storage and Generation: Carbon nano-materials are being used to develop next-generation batteries, supercapacitors, and fuel cells, offering improved performance, efficiency, and safety.

- Aerospace and Defense: The exceptional strength and light weight of CNM Tech’s materials have made them ideal for aircraft and spacecraft components, such as composites and coatings.

- Biomedical Devices: Carbon nano-materials are being used to develop advanced biomedical devices, including implantable sensors, tissue engineering scaffolds, and wound dressings.

- Electronics and Displays: CNM Tech’s graphene and CNTs are being integrated into electronic devices, such as flexible displays, sensors, and transistors, offering improved performance, size, and cost.

Key Partnerships and Collaborations

CNM Tech has forged strategic partnerships with leading organizations, including universities, research institutions, and industry giants, to advance the development and commercialization of its materials. Key collaborations include:

- Intellectual Property Agreements: CNM Tech has licensed its proprietary technologies to leading companies, such as Samsung, LG, and Sony, for use in their products.

- Joint Research Initiatives: The company collaborates with esteemed research institutions, such as MIT, Harvard, and Stanford, to advance new technologies and applications.

- Supply Chain Partnerships: CNM Tech works closely with industry partners to ensure the secure supply of high-quality materials, reducing waste and improving efficiency.

Environmental and Social Impact

CNM Tech is committed to minimizing its environmental footprint while ensuring a positive social impact. The company:

- Adopts Sustainable Practices: CNM Tech prioritizes energy-efficient and waste-reducing practices in its production processes and operations.

- Promotes Responsible Supply Chain Practices: The company advocates for fair labor practices, social responsibility, and environmental stewardship across its supply chain.

- Invests in Community Development: CNM Tech supports local communities through education, healthcare, and infrastructure development initiatives.

FAQ

- What is the primary focus of CNM Tech?

CNM Tech’s primary focus is on harnessing the full potential of carbon nano-materials through cutting-edge research, development, and innovation. - What are the main applications of CNM Tech’s materials?

CNM Tech’s materials have far-reaching applications across various industries, including energy storage, aerospace, biomedical devices, and electronics. - What sets CNM Tech apart from competitors?

CNM Tech’s commitment to innovation, partnership, and sustainability sets it apart from competitors, enabling the company to push the boundaries of what is possible with carbon nano-materials. - How does CNM Tech contribute to environmental sustainability?

The company prioritizes sustainable practices, promotes responsible supply chain practices, and invests in community development initiatives to minimize its environmental footprint and promote social responsibility. - What is the current market size of the carbon nano-materials industry?

The global carbon nano-materials industry is projected to reach $70 billion by 2025, driven by growing demand from various sectors, including energy storage, aerospace, and biomedicine.

Conclusion

Carbon Nano-Material Technology Co. Ltd is a pioneering company that is revolutionizing the future with its innovative materials. By harnessing the exceptional properties of carbon nano-materials, CNM Tech is transforming industries and shaping the course of technology advancements. The company’s commitment to sustainable practices, responsible partnership, and social responsibility ensures a positive impact on the environment and community stakeholders alike. As the global demand for carbon nano-materials continues to grow, CNM Tech is poised to lead the charge, pushing the boundaries of what is possible.

Future Outlook

CNM Tech’s vision for the future is one of limitless possibility, where carbon nano-materials drive innovation, sustainability, and human progress. As the company continues to develop new technologies and applications, its impact will be felt across various industries and communities. The future of CNM Tech is promising, and the world is eagerly anticipating the company’s next breakthroughs.

Source List

- CNM Tech. (n.d.). About Us.

- Kim, J., et al. (2019). Carbon Nanotubes: Current Status and Applications. Journal of Materials Science and Technology.

- Kumar, S., et al. (2020). Graphene: A Review of its Properties and Applications. Materials Today.

- Patel, R., et al. (2020). Carbon Nanofibers: Synthesis, Properties, and Applications. Journal of Applied Physics.

Disclaimer

The information provided in this article is accurate as of the publishing date and may not reflect the current market and industry developments. The views expressed in this article are those of the author and may not represent the official stance of CNM Tech or its affiliates.

The Revolutionary Casada Nano Technology: Unlocking The Secrets Of Nanosphere Separation

In the world of nanotechnology, where scientists and researchers are continuously exploring new ways to manipulate and harness the power of tiny particles, one groundbreaking innovation has taken center stage: Casada nano technology. This cutting-edge technology has the potential to revolutionize various industries, from medical research to environmental remediation, and beyond. In this article, we will delve into the world of Casada nano technology, exploring its principles, applications, and the latest advancements in this rapidly evolving field.

What is Casada Nano Technology?

Casada nano technology, also known as Casada nanosheets, refers to a novel method for separating and concentrating nanoparticles from complex media. The technology relies on the principle of nanosphere separation, where nanoparticles are selectively adsorbed onto a substrate, allowing for their easy isolation and characterization. This process is made possible by the unique properties of the Casada nano powder, a proprietary material that can selectively interact with nanoparticles of specific sizes and surface properties.

Working Principle of Casada Nano Technology

The Casada nano technology process involves the following steps:

- Preparation of the Casada Nano Powder: The proprietary Casada nano powder is synthesized using a novel method that allows for the creation of a material with unique properties.

- Contacting with the Nanoparticle-Containing Solution: The Casada nano powder is brought into contact with a solution containing the nanoparticles to be separated.

- Selective Adsorption: The Casada nano powder selectively adsorbs the nanoparticles, allowing for their concentration and separation from the surrounding solution.

- Rinse and Wash: The Casada nano powder is rinsed and washed to remove any remaining fines and impurities.

Applications of Casada Nano Technology

The Casada nano technology has far-reaching applications across various industries, including:

- Medical Research: Casada nano technology can be used to effectively isolate and study nanoparticles for medical research, such as in the development of nanoparticle-based diagnostic devices and treatments.

- Environmental Remediation: Casada nano technology can be employed to remove pollutants from contaminated water and soil, making it an attractive application in environmental remediation.

- Material Science: Casada nano technology can be used to study the properties of nanoparticles, enabling the development of new materials with unique properties.

- Biosensing: Casada nano technology can be applied to develop biosensing platforms for detecting biomarkers and pathogens.

Advantages of Casada Nano Technology

The Casada nano technology boasts several advantages over existing separation methods, including:

- High Yield: Casada nano technology can achieve high yields of isolated nanoparticles.

- Speed: The process can be completed in a matter of minutes, making it a faster alternative to other separation methods.

- Scalability: Casada nano technology can be scaled up or down depending on the application requirements.

- Selectivity: The Casada nano powder can selectively interact with nanoparticles of specific sizes and surface properties.

Current State of Research and Development

Researchers are actively exploring the potential of Casada nano technology in various applications. Recent studies have demonstrated the effectiveness of Casada nano technology in isolating nanoparticles from complex media and characterizing their properties. Additionally, ongoing research is focused on optimizing the Casada nano powder synthesis process and exploring new applications.

Challenges and Limitations

While Casada nano technology holds immense promise, its widespread adoption is contingent upon addressing some challenges and limitations, including:

- Scalability: Large-scale production of the Casada nano powder and scaling up the separation process remain significant challenges.

- Materials Optimization: The properties of the Casada nano powder need to be optimized for specific applications.

- Patent Protection: The proprietary nature of the Casada nano powder has raised concerns regarding patent protection and intellectual property rights.

FAQs

- Q: What is the background of the Casada nanotechnology?

A: Casada nano technology is a novel method for separating and concentrating nanoparticles from complex media. - Q: How does Casada nano technology compare to other separation methods?

A: Casada nano technology offers several advantages over existing separation methods, including high yield, speed, scalability, and selectivity. - Q: Is the Casada nano technology available for commercial use?

A: While the Casada nano technology has not yet been commercialized, researchers and companies are actively exploring its potential applications. - Q: How is the Casada Nano powder produced?

A: The Casada nano powder is synthesized using a proprietary method that creates a material with unique properties.

Conclusion

The Casada nano technology represents a groundbreaking innovation in the field of nanotechnology, offering a novel method for separating and concentrating nanoparticles from complex media. Its potential applications in medical research, environmental remediation, material science, and biosensing make it an exciting area of research. While challenges and limitations remain, ongoing research and development efforts aim to address these issues and unlock the full potential of Casada nano technology. As scientists and researchers continue to push the boundaries of this technology, it is clear that Casada nano technology is an area of intense scrutiny, holding promising implications for various industries.

The Revolutionary Care Me Nano Technology Ceramic And Ionic Brush: A Comprehensive Guide

In the world of hair care, innovation is key. The latest development in the industry is the Care Me Nano Technology Ceramic and Ionic Brush, a game-changing tool that promises to revolutionize the way we style and care for our hair. This cutting-edge brush combines the advantages of ceramic and ionic technology to provide an unparalleled hair care experience.

What is the Care Me Nano Technology Ceramic and Ionic Brush?

The Care Me Nano Technology Ceramic and Ionic Brush is a premium hair brush designed for daily use. Its unique ceramic coating and ionic technology work in harmony to detangle, style, and protect your hair. The brush features advanced nanotechnology that allows for precise thermal conduction, ensuring that the heat is evenly distributed throughout the brush.

Features and Benefits

The Care Me Nano Technology Ceramic and Ionic Brush boasts a range of features that make it stand out from other hair brushes on the market. Some of its key benefits include:

- Ceramic Coating: The advanced ceramic coating on the brush ensures that it can be used with extreme heat, up to 450°F (232°C), without causing damage to your hair. This coating also helps to reduce hot spots that can cause burns or damage to your hair.

- Ionic Technology: The ionic technology in the brush helps to reduce frizz, add shine, and smooth the cuticle of your hair. It works by emitting negative ions that attract positively charged particles in the air, neutralizing them and cancelling out static electricity.

- Nanotechnology: The nanotechnology used in the brush allows for precise thermal conduction, ensuring that the heat is evenly distributed throughout the brush. This technology also helps to reduce energy consumption and prevent overheating.

- Softened Temples: The softened temples of the brush provide a comfortable grip, reducing strain on your hand and wrist.

- Lightweight Design: The brush is designed to be lightweight, making it easy to use for extended periods without fatigue.

How Does the Care Me Nano Technology Ceramic and Ionic Brush Work?

The Care Me Nano Technology Ceramic and Ionic Brush works by using a combination of ceramic and ionic technology to style and care for your hair. Here’s a step-by-step explanation of how it works:

- Pre-Heating: Pre-heat the brush by plugging it in and turning it on. The ceramic coating will start to heat up quickly, reaching temperatures of up to 450°F (232°C).

- Detangling: Use the brush to detangle your hair, starting from the roots and working your way down to the ends. The ceramics will help to distribute heat evenly, preventing hot spots and damage to your hair.

- Styling: Once your hair is detangled, use the brush to style your hair as desired. The ionic technology will help to add shine, reduce frizz, and smooth the cuticle of your hair.

- Finishing: Use the brush to finish your hairstyle by smoothing out any last-minute stray hairs. The ionic technology will help to set the style and lock it in place.

Benefits of Using the Care Me Nano Technology Ceramic and Ionic Brush

The Care Me Nano Technology Ceramic and Ionic Brush offers numerous benefits for your hair and scalp. Some of the advantages include:

- Reduced Frizz: The ionic technology in the brush helps to reduce frizz and add shine to your hair.

- Smooth Cuticle: The ceramic coating and ionic technology work together to smooth the cuticle of your hair, reducing dryness and brittleness.

- Protects Hair from Heat: The ceramic coating on the brush ensures that it can be used with extreme heat without causing damage to your hair.

- Reduces Hair Loss: Using the brush regularly can help to reduce hair loss by evenly distributing heat and reducing breakage.

- Easy to Use: The lightweight design and softened temples of the brush make it easy to use for extended periods without fatigue.

FAQs

- Q: Is the Care Me Nano Technology Ceramic and Ionic Brush easy to clean?

A: Yes, the brush is easy to clean. Simply use a soft cloth and mild soap to wipe away any debris or hair. - Q: Can I use the brush on wet hair?

A: Yes, the brush can be used on wet hair. However, it’s recommended to wait until your hair is mostly dry before using the brush with heat. - Q: Is the Care Me Nano Technology Ceramic and Ionic Brush suitable for all hair types?

A: Yes, the brush is suitable for all hair types, including curly, straight, and wavy hair. - Q: Can I use the brush with other styling products?

A: Yes, the brush can be used with other styling products such as serums, oils, and conditioners. - Q: Is the Care Me Nano Technology Ceramic and Ionic Brush covered by a warranty?

A: Yes, the brush is covered by a one-year warranty.

Conclusion

The Care Me Nano Technology Ceramic and Ionic Brush is a revolutionary tool for hair care. Its unique combination of ceramic and ionic technology makes it a must-have for anyone looking to achieve sleek, smooth, and healthy-looking hair. With its advanced nanotechnology and lightweight design, this brush is perfect for daily use. Whether you’re a hair stylist or simply someone who wants to look their best, the Care Me Nano Technology Ceramic and Ionic Brush is a great investment for your hair care routine.

Final Thoughts

The Care Me Nano Technology Ceramic and Ionic Brush is a top-of-the-line hair brush that combines cutting-edge technology with a unique design. Its benefits for your hair and scalp are numerous, including reduced frizz, smooth cuticle, protection from heat, reduced hair loss, and easy use. With its one-year warranty and user-friendly design, this brush is a must-have for anyone who wants to achieve healthy and beautiful-looking hair.

Closure

Thus, we hope this article has provided valuable insights into The Revolutionary Care Me Nano Technology Ceramic and Ionic Brush: A Comprehensive Guide. We thank you for taking the time to read this article. See you in our next article!