Wood has been a vital part of human civilization for centuries, used for everything from building homes to creating furniture. However, traditional wood products have several limitations, including susceptibility to rot, insect damage, and limited durability. To address these issues, researchers have been working on developing advanced wood nano technology, which involves manipulating wood at the nanoscale to create new materials with enhanced properties. In this article, we will delve into the world of advanced wood nano technology, exploring its benefits, applications, and potential impact on the wood industry.

What is Wood Nano Technology?

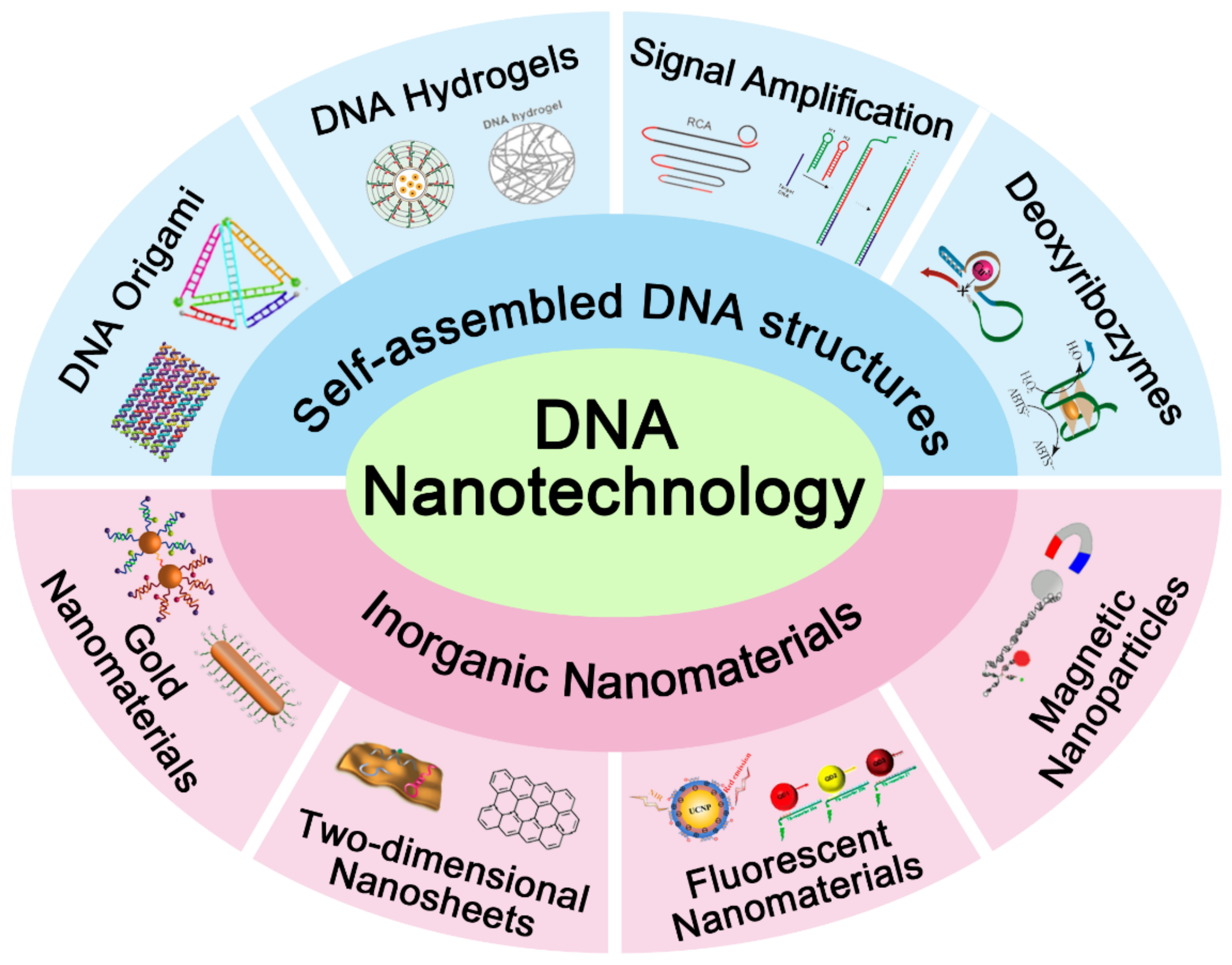

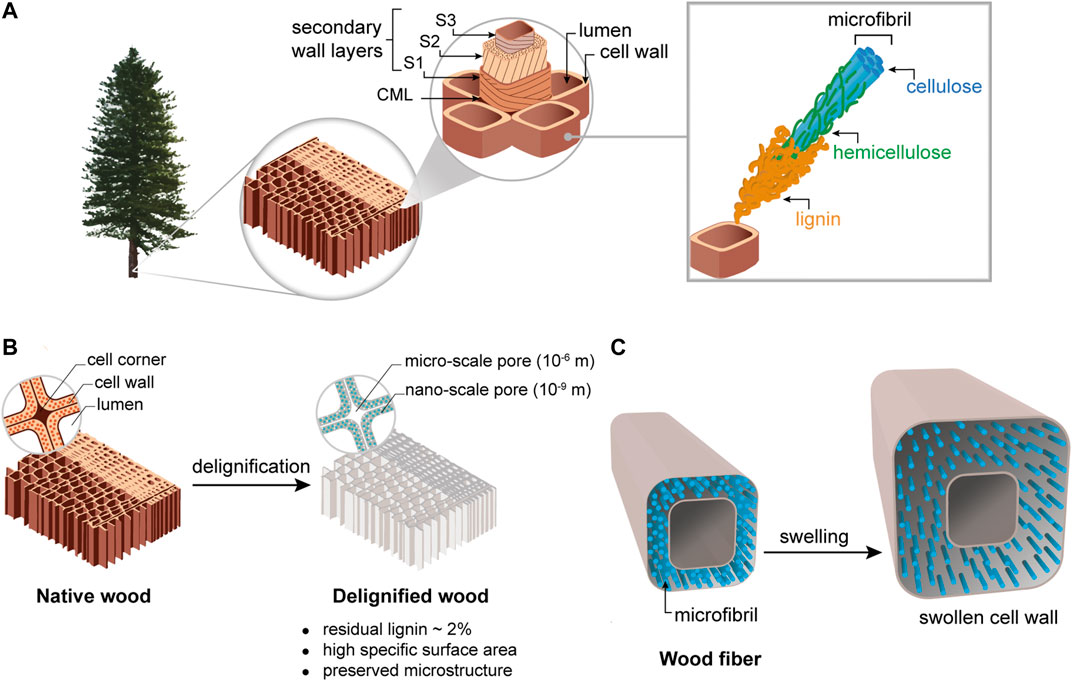

Wood nano technology involves the use of nanotechnology to modify the properties of wood. This is achieved by breaking down wood into its constituent parts, such as cellulose, hemicellulose, and lignin, and then reassembling them into new materials with improved properties. The resulting materials are known as nanocellulose, which can be used to create a wide range of products, including paper, packaging materials, and even biomedical implants.

Benefits of Advanced Wood Nano Technology

Advanced wood nano technology offers several benefits over traditional wood products. Some of the most significant advantages include:

- Enhanced durability: Wood nano materials are more resistant to decay, insect damage, and other forms of degradation, making them ideal for use in applications where durability is crucial.

- Improved strength: Nanocellulose materials have been shown to have higher strength-to-weight ratios than traditional wood products, making them suitable for use in construction and other high-performance applications.

- Increased sustainability: Wood nano technology can help reduce waste and improve the efficiency of wood production, as it allows for the use of lower-quality wood and other biomass sources.

- Customizable properties: By manipulating the structure and composition of wood at the nanoscale, researchers can create materials with tailored properties, such as optical, electrical, or thermal properties.

Applications of Advanced Wood Nano Technology

The potential applications of advanced wood nano technology are vast and varied. Some of the most promising areas of research include:

- Construction materials: Wood nano materials could be used to create stronger, more durable building materials, such as beams, panels, and insulation.

- Packaging materials: Nanocellulose-based packaging materials could offer improved barrier properties, reducing the need for plastic packaging and minimizing waste.

- Biomedical implants: Wood nano technology could be used to create biocompatible, biodegradable implants for medical applications, such as tissue engineering and wound healing.

- Energy storage: Researchers are exploring the use of wood nano materials in energy storage devices, such as batteries and supercapacitors.

Current Research and Development

Several research institutions and companies are actively working on developing advanced wood nano technology. Some of the current research areas include:

- Nanocellulose production: Researchers are developing new methods for producing nanocellulose, including mechanical, chemical, and enzymatic approaches.

- Material modification: Scientists are exploring ways to modify the properties of nanocellulose materials, such as through the addition of nanoparticles or other functional materials.

- Scalability and commercialization: Efforts are underway to scale up wood nano technology and make it commercially viable, including the development of pilot plants and production facilities.

Challenges and Limitations

While advanced wood nano technology holds great promise, there are several challenges and limitations that must be addressed. Some of the key issues include:

- Cost: The production of nanocellulose materials can be expensive, making them less competitive with traditional wood products.

- Scalability: Currently, the production of wood nano materials is limited to small batches, and scaling up production while maintaining quality and consistency is a significant challenge.

- Standardization: There is a need for standardization in the production and characterization of wood nano materials to ensure consistency and quality.

FAQ

- What is the difference between nanocellulose and microcellulose?

Nanocellulose refers to cellulose fibers with diameters in the range of 1-100 nanometers, while microcellulose refers to fibers with diameters in the range of 1-100 micrometers. - Is wood nano technology sustainable?

Yes, wood nano technology has the potential to be highly sustainable, as it can reduce waste and improve the efficiency of wood production. - What are the potential health risks associated with wood nano technology?

The health risks associated with wood nano technology are still being researched, but preliminary studies suggest that nanocellulose materials are biocompatible and non-toxic. - Can wood nano technology be used to create new wood products?

Yes, wood nano technology can be used to create new wood products with improved properties, such as strength, durability, and sustainability.

Conclusion

Advanced wood nano technology has the potential to revolutionize the wood industry by creating new materials with enhanced properties. While there are still challenges and limitations to be addressed, the benefits of wood nano technology, including improved durability, strength, and sustainability, make it an exciting and promising field of research. As researchers continue to develop and refine wood nano technology, we can expect to see new and innovative wood products emerge, offering improved performance, sustainability, and functionality. With its potential to reduce waste, improve efficiency, and create new materials, advanced wood nano technology is an important step towards a more sustainable future for the wood industry.

Closure

Thus, we hope this article has provided valuable insights into Advanced Wood Nano Technology: A Sustainable Future for Wood Products. We appreciate your attention to our article. See you in our next article!