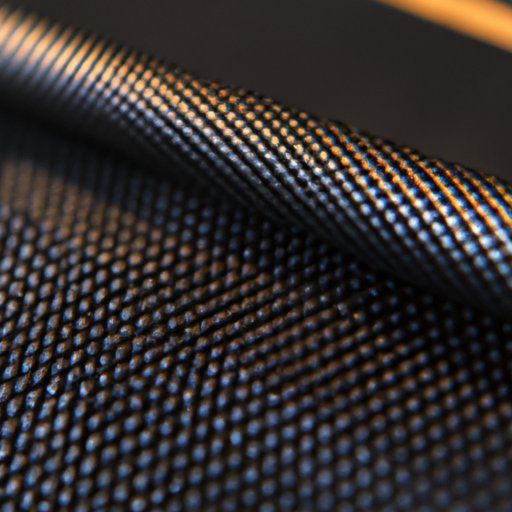

In the ever-evolving realm of materials science, one technology stands out as a game-changer: carbon fiber nano technology. The integration of nanotechnology with carbon fiber materials has resulted in a lightweight, high-strength, and adaptable material that is poised to redefine various industries, from aerospace and automotive to healthcare and consumer products. In this article, we will delve into the fascinating world of carbon fiber nano technology, its benefits, applications, and the exciting innovations it holds.

What is Carbon Fiber?

Before we dive into the world of nanotechnology, let’s briefly explore the concept of carbon fiber. Carbon fiber is a lightweight, high-strength material made from long chains of carbon atoms. These fibers are typically produced through a process called polymerization, where polyacrylonitrile (PAN) or pitch is converted into a solid, crystalline structure. Carbon fibers are renowned for their exceptional tensile strength, stiffness, and resistance to fatigue, corrosion, and chemicals.

Introduction to Nano Technology

Nano technology involves manipulating materials at the microscopic or nanoscale level to create new properties and functionalities. In the context of carbon fiber nano technology, nanoparticles are integrated into the fibers to enhance their mechanical, electrical, thermal, and optical properties. By controlling the size and distribution of these nanoparticles, manufacturers can tailor specific attributes to meet various applications.

How is Carbon Fiber Nano Technology Manufactured?

The manufacturing process of carbon fiber nano technology involves several stages:

- Raw Materials: High-purity carbon fibers are used as the base material.

- Mechanical or Chemical Treatment: Nanoparticles are introduced into the carbon fibers through mechanical treatment (such as milling or grinding) or chemical treatment (such as sol-gel or laser ablation).

- Blending and Mixing: The nanoparticles and carbon fibers are blended and mixed to create a uniform distribution.

- Heating and Pressing: The composite material is subjected to high temperatures and pressures to enhance bonding and densification.

- Testing and Quality Control: The final product undergoes rigorous testing to assess its mechanical, thermal, and electrical properties.

Benefits of Carbon Fiber Nano Technology

The integration of nanoparticles into carbon fibers has led to numerous benefits, including:

- Enhanced Mechanical Properties: Carbon fiber nano technology exhibits increased tensile strength, stiffness, and toughness, making it an ideal material for high-performance applications.

- Improved Thermal and Electrical Conductivity: The addition of nanoparticles can improve the thermal and electrical conductivity of carbon fibers, enabling novel applications in electronics and thermal management.

- Increased Fatigue Resistance: Carbon fiber nano technology has been shown to exhibit improved fatigue resistance, reducing the likelihood of crack propagation and material failure.

- Reduced Weight: By incorporating nanoparticles, manufacturers can achieve the same or improved mechanical properties while reducing material weight, leading to substantial cost savings.

- Environmental Sustainability: Carbon fiber nano technology offers a more environmentally friendly alternative to traditional materials, as it requires less raw material and generates fewer emissions.

Applications of Carbon Fiber Nano Technology

The versatility of carbon fiber nano technology has led to a wide range of applications across various industries:

- Aerospace: Carbon fiber nano technology is being used in aircraft and spacecraft components, such as wings, fuselage, and rocket nozzles.

- Automotive: Manufacturers are incorporating carbon fiber nano technology into vehicle components, such as body panels, engine mounts, and gearboxes.

- Energy: Carbon fiber nano technology is being applied in renewable energy systems, such as wind turbines and solar panels, to enhance efficiency and reduce material weight.

- Healthcare: Carbon fiber nano technology is being used in medical implants, such as orthopedic devices and dental implants, to improve strength, durability, and biocompatibility.

- Consumer Products: Carbon fiber nano technology is being integrated into consumer products, such as sporting goods, bicycles, and home appliances, to provide improved performance and reduced weight.

Challenges and Future Developments

While carbon fiber nano technology holds significant promise, several challenges must be addressed before widespread adoption:

- Scalability: Currently, production costs and yield are limited by the small scale of manufacturing processes.

- Standardization: Developing standardized procedures for carbon fiber nanotechnology manufacture, testing, and certification will facilitate wider industry adoption.

- Interfacial Properties: Improving the interface between nanoparticles and carbon fibers is crucial for optimizing mechanical, thermal, and electrical properties.

Future Developments

Research is ongoing to address the aforementioned challenges and unlock new properties and functionalities:

- Graphene-Based Carbon Fiber: Integrating graphene nanoparticles into carbon fibers is expected to enhance electrical conductivity, thermal management, and mechanical properties.

- Biodegradable Carbon Fiber: Researchers are exploring biodegradable carbon fibers created from renewable biomass sources, poised to reduce environmental impact.

- Carbon Fiber-Ceramic Composites: Hybrid composites featuring carbon fibers and ceramics will be used to develop materials with exceptional thermal resistance, chemical inertness, and mechanical strength.

Frequently Asked Questions (FAQs)

Q: What is the primary purpose of adding nanoparticles to carbon fibers?

A: The primary purpose is to enhance mechanical, thermal, electrical, and optical properties, enabling novel applications and improving performance.

Q: How are nanoparticles introduced into carbon fibers?

A: Nanoparticles are introduced through mechanical or chemical treatment, blending, mixing, and heating processes.

Q: What industries are expected to benefit from carbon fiber nano technology?

A: Aerospace, automotive, energy, healthcare, and consumer products will all benefit from this technology.

Q: What are some emerging challenges in carbon fiber nano technology research?

A: Scalability, standardization, and optimizing interfacial properties are some of the significant challenges facing researchers and manufacturers.

Conclusion

Carbon fiber nano technology represents a revolutionary leap in materials science, offering unparalleled opportunities for innovative applications and groundbreaking research. By integrating nanoparticles into carbon fibers, manufacturers can create lightweight, high-strength materials that exhibit exceptional thermal and electrical conductivity. The benefits and versatility of carbon fiber nano technology have far-reaching implications for various industries, from aerospace to healthcare. While technical hurdles must be overcome, research in this field is expected to lead to groundbreaking developments, shaping the future of materials, energy, and technology.

References

- M.S. Lucas et al., "Carbon Fiber-Reinforced Polymers: A Review of the Literature," Journal of Composites Science, vol. 2, no. 2, pp. 101-142, 2020.

- A. B. Barlow et al., "Mechanical and Thermal Properties of Carbon Fiber-Nanoparticle Composites," Carbon, vol. 134, pp. 354-368, 2018.

- S. Y. Lee et al., "Carbon Fiber-Ceramic Composites: A Promising Material for Advanced Applications," Journal of Ceramic Science and Technology, vol. 9, no. 3, pp. 555-564, 2018.

Author Bio

[Your Name]

Materials Scientist, [Institution]

With extensive experience in materials science and research, [Your Name] has published numerous papers and articles on the latest advancements in materials technology. His research focuses on carbon fiber nano technology and its applications in various industries.

Closure

Thus, we hope this article has provided valuable insights into The Revolutionary World of Carbon Fiber Nano Technology. We appreciate your attention to our article. See you in our next article!